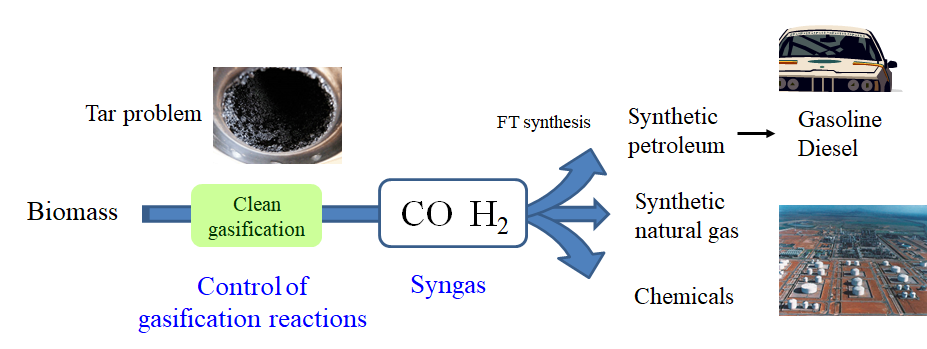

Gasification, which is the high-temperature process normally conducted at >800˚C, converts biomass into the gaseous products (CO, H2, methane, etc.) in short residence time. The producer gas can be utilized for engine and turbine to generate electricity more efficiently than the steam turbine process. Furthermore, synthetic petroleum can be produced by catalytic conversion of the producer gas (syngas, CO + H2), which is known as FT (Fischer Tropsch) synthesis and BTL (biomass to liquid) technology. All these processes are proven technologies based on fossil resources such as natural gas and coal and already commercialized. Accordingly, the key technology for these applications is “clean gasification” of biomass.

The major drawback is “tar problem”, which includes the clogging of the pipeline from gasifier and deactivation of FT catalysts through coking. Even though many attempts have been conducted to solve the tar problem mainly from the viewpoint of the chemical engineering field, clean gasification processes have not been established yet. In our laboratory, clean gasification by the mitigation of tar problem has been approached in the viewpoint of the molecular mechanisms of pyrolysis and secondary reactions stages, particularly focusing on the reactivities of the biomass-derived gasification intermediates.

Biorefinery with clean biomass gasification

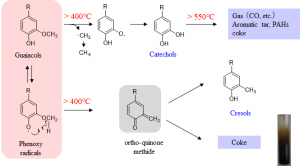

Tar formation and coking mechanisms proposed for lignin

Experimental set up for biomass gasification